- Press

THE QUINTESSENCE OF ART AND CRAFT IN WATCHMAKING

When talking about luxury watches, everyone thinks of famous brands from Switzerland for their precision and meticulousness in every detail. Most notably, the watch with the Cloisonné enamel dial is not only has material value but also carries artistic value for its owner.

Cloisonné enamel is a traditional art that has been around for a long time and is one of the most complex and demanding enamel techniques, requiring high skill.

Philippe Mark’s artisans shaping Cloisonné gold wires for the design

Philippe Mark’s artisans apply the Cloisonné enamel technique, creating patterns on the dial with gold wires that are 0.03mm thick. The ultra-thin gold wires are carefully bent and arranged on the dial to separate and partition each color to shape the final dial.

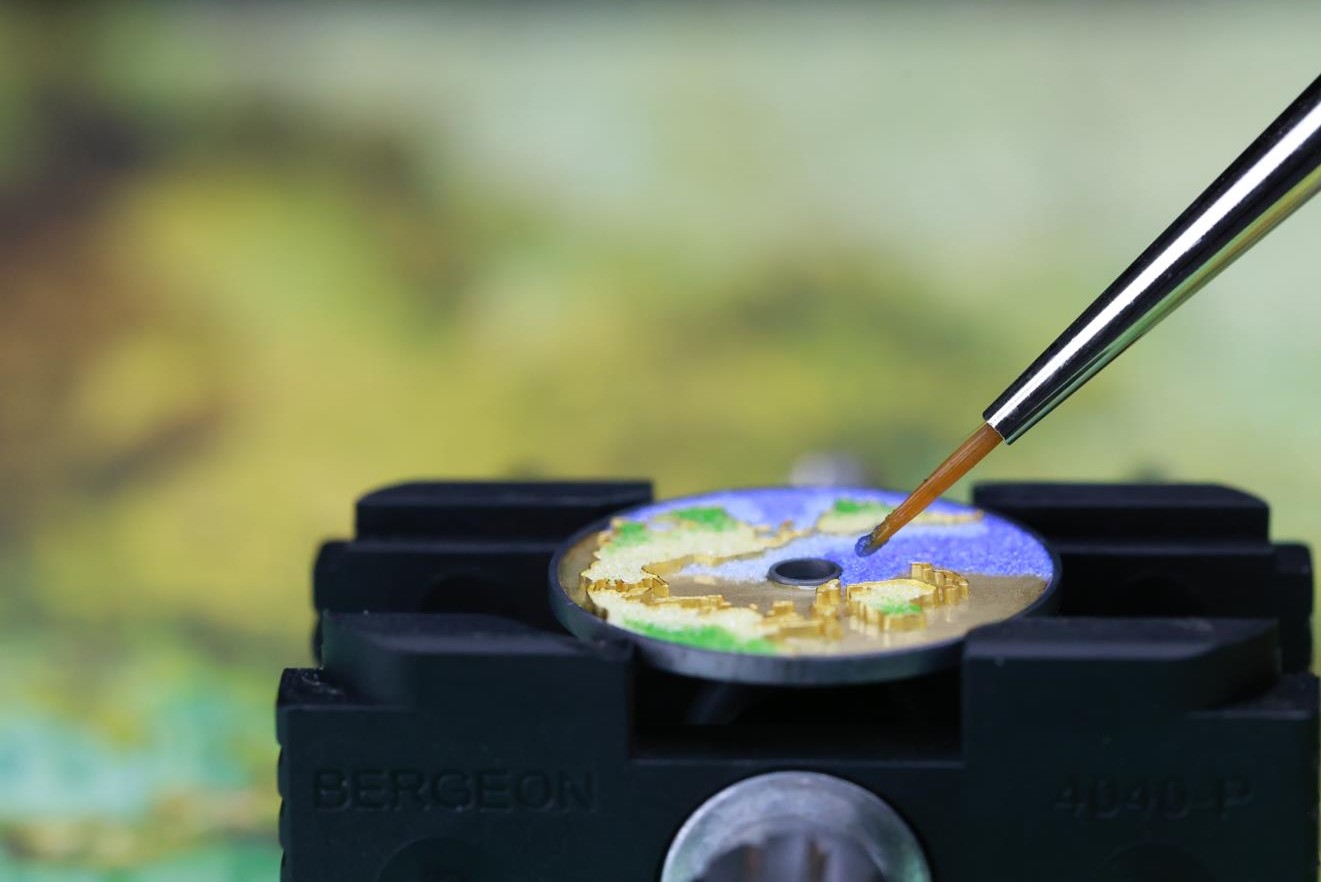

Philippe Mark’s artisans coats the Cloisonné enamel over the gold dial

Philippe Mark’s artisans applying Cloisonné enamel onto the gold dial the Cloisonné enamel production process requires delicacy, meticulousness, and patience. The Cloisonné artisan has to work with the highest concentration and precision to ensure that the gold wires are properly bent to the correct size and placed in the corect position according to the sample. Moreover, filling the empty spaces with enamel requires skill and perseverance to ensure that the enamel is evenly and smoothly filled.

The curves and colors of the dial are created by the skilled hands of the artisans, then filled with enamel and fired at a temperature of 700 to 900 degrees Celsius in a specialized kiln. This process is repeated 12 to 15 times before surface polishing. Through each firing, the enamel face is at high risk of cracking, defects, air bubbles, excessive luster, color changes, or unwanted damages, resulting in an 80% rejection rate. Therefore, the success rate of creating a perfect Cloisonné enamel face is too low.

Careful checking ensures product perfection

In addition to the meticulousness in creating the Cloisonné enamel dial, other detail of the watch also require perfection and meticulousness in each stage.

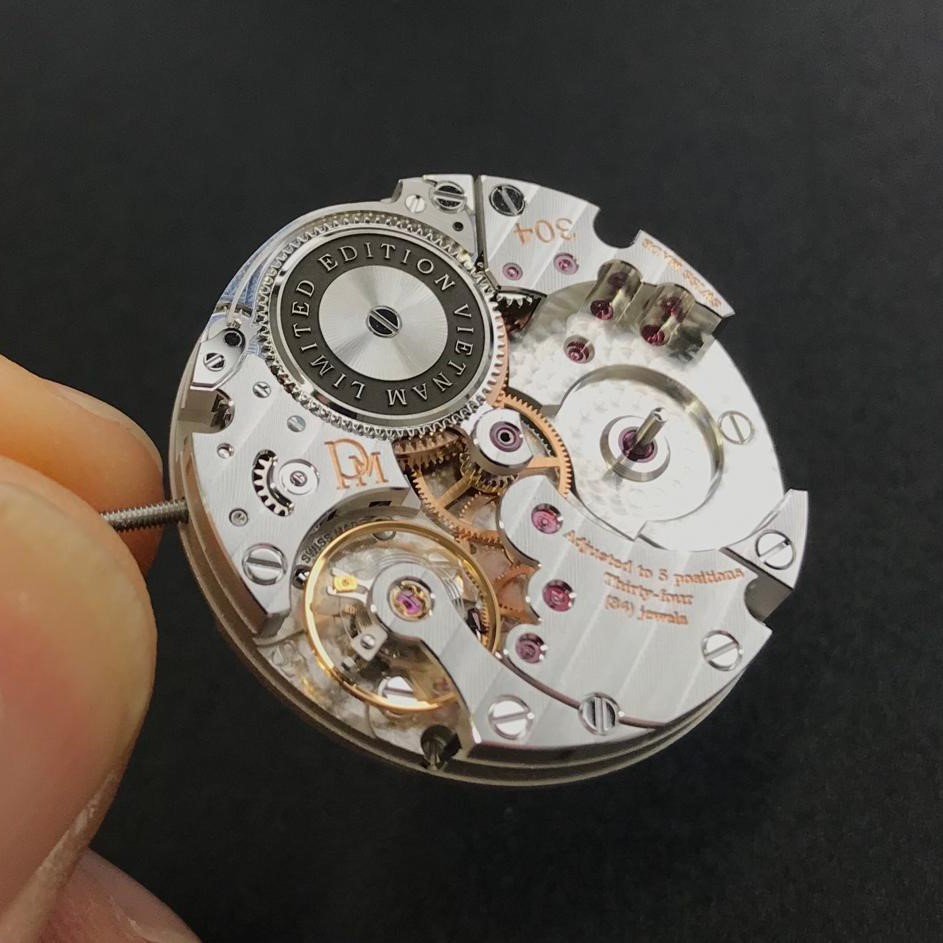

PM 304 movement with intricate details

The application of advanced techniques, advanced technologies to produce watch parts, along with hours of manual operations by experienced watchmakers have created mechanical masterpieces.

The case is finished by CNC technology

In addition to that, there is a rigorous quality control process at every stage of production, assembly, adjustment, and accuracy testing, carried out strictly and meticulously by the stringent quality supervision according to Swiss standards of Schwarz Etienne (a watch manufacturing unit with more than 120 years of experience). To ensures that Philippe Mark's products are manufactured to meet the highest quality standards and provide reliability and credibility to users worldwide.

Schwarz Etienne's inspection